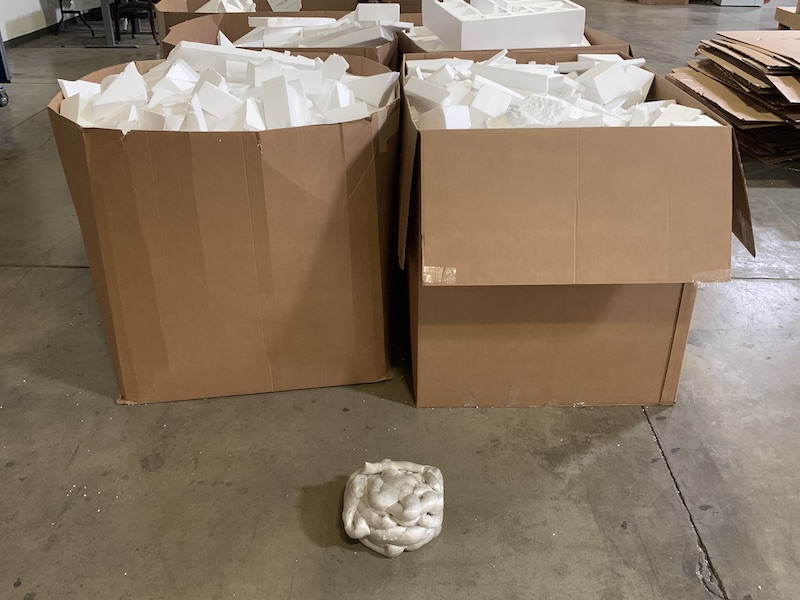

At iNSPIRE Q, we aim to deliver exclusively designed and expertly crafted furniture. However, we realize that—quite literally—delivering our products leaves a massive carbon footprint. With boxes and boxes overflowing with Styrofoam, something had to be done.

So, we’re going to melt it!

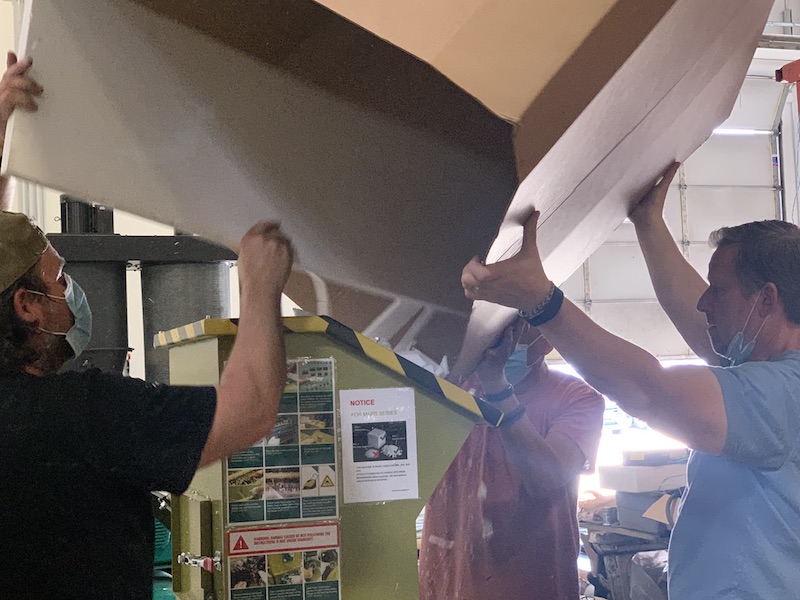

One of our warehouses for iNSPIRE Q products recently purchased the GREENMAX Melter Mars C50 from INTCO Recycling. This machine is designed to help reduce, reuse, and recycle packaging waste. At 56 in. wide, 43 in. deep, and 63 in. high, this impressive machine has a compression ratio of 90:1 and a production capacity of 110 lbs. of Styrofoam per hour.

And this machine can compress a variety of materials, including polystyrene, polyethylene, and polypropylene. We primarily use expanded polystyrene in our packaging, which is what we know most commonly as Styrofoam.

But how does it work?

The GREENMAX Melter Mars C50 is quite easy to use! All you have to do is turn it on and drop the expanded polystyrene in the top. We don’t need to make adjustments; we just feed it the Styrofoam and let the magic happen! With screw melting technology, the machine just uses heat and pressure to melt and condense the expanded polystyrene. This process is quick, safe, and completely nontoxic, both for humans and the environment!

The condensed polystyrene flows out of the machine as solid ingots. The ingots weigh about 18 lbs., which makes it easy for us to stack. This is much better than having boxes overflowing with expanded polystyrene laying around. GREENMAX then buys back the ingots for proper recycling. This is just one small way iNSPIRE Q can reduce, reuse, and recycle.

At iNSPIRE Q, we strive to deliver high-quality furniture, but not at a high cost to you or the environment. Packaging alone has always been one of the biggest contributors to solid waste in the United States. But with the GREENMAX Melter Mars C50, we can start eliminating our Styrofoam waste. It is one of many small steps to come, but we are here to do our part to build a better, greener future.

If you’d like to know more about how #iNSPIREQCARES, be sure to visit our YouTube channel or check out our other blog posts.